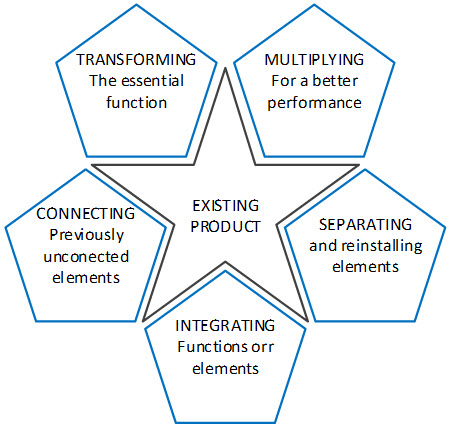

Searching for new opportunities for the re-design and upgrade etc. of products whose life cycle is coming to an end; these are relatively easy to accomplish and market, as they derive from existing sources. The method consists of the following phases:

- Transformation (redesign through removal and replacement of the requisite or essential function, or upgrade/modernization of the existing function)

- Multiplication (the selected part is multiplied for better performance)

- Separation (some vital parts are split or subdivided to create a new composition of the product)

- Integration (functional elements of a product are assigned new tasks, else they are merged or integrated)

- Connection (creating new connections between elements that were previously unconnected, or reconfiguring the existing connections).

The scheme described in figure: Innovating a product from existing sources can be used in implementing the various individual phases of the methodology. It is not necessary to follow the written order of the phases. Each step of the scheme may be carried out independently of the others, and also, depending on the product under consideration, it is not necessary to complete all the phases. It is, however, essential to focus on the existing situation and resources available when looking for opportunities. In essence, we should detect – based on the analysis of the product – which of its elements and/or functions hinder the continuation of its life (market) cycle. Thus, the identified problematic or obsolete elements of the product can be re-designed or renewed and updated to extend its lifecycle. The key feature of this method is that we innovate only by starting from the status quo and the already available resources. The Quick and Dirty Innovation Method (QaDIM), where a similar principle of innovation is implemented, is not limited by the resources, since we innovate on the basis of the potential of an existing product.

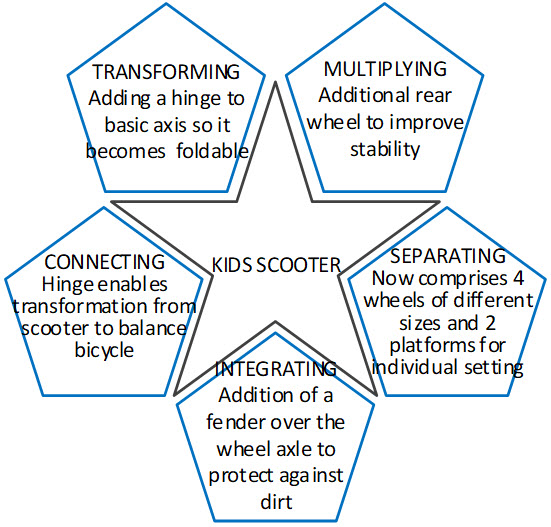

Example: A manufacturer of baby toys has seen a drop in the sales of its push scooter; this is mainly due to cheaper, but lower quality, imports from eastern markets. Due to extant high production quality and commensurately high material costs, the price of the product could not be significantly lowered, thus it was decided to seek opportunities to maintain market position through improvements to the existing manufacture. Their target customers were young, active parents, and the company was thinking mainly in the direction of addressing their specific needs and lifestyle. They gathered together a focus group, consisting of the push-scooter designers, young parents, marketers or retailers.

The company was looking for opportunities only by taking into account the existing elements of the product and the available resources, i.e. it did not want to develop a new product. In addition to the now added possibility of the simple transformation from a push scooter into a balance bicycle, potential for extending the lifespan of the product were found in the folding option for easy carrying when the child gets tired; adding wheels for greater stability; individualized configuration depending on the child’s circumstances and the specifics of the terrain, as well as adding protection from dirt. The company’s decision thence to manufacture the combination scooter – balance bicycle proved to be a good one, as it was most successful on the market.

Comprehensive idea creation process based on the existing elements of the product and the available resources.

This method takes more time, at least 2 to 3 days, because it is necessary to carefully examine the various aspects of the existing product and options in order to perceive all the possibilities and opportunities.

The method is usually carried out in a group.