- Accedi o registrati per poter commentare

Prototyping is a process where the ideas are materialised – turned from ideas, scetches into tangible forms. Basic idea is to test and present your idea. It is also called Proof of Concept.

The first, very simple prototype if called pretotype (Picture 1). It is a simple way of materialisation ideas before attempting to actually prototype it.

- often made in some hours or one day

- intended for ourselves (or for presentations to our loved ones)

- basic idea is formed

- we get an idea and insight into future challenges – conceptual, development, technology, cost

Their purpose is:

- To convince you that your idea works.

- To enable you to solve or at least identify technical and design problems.

- To enable you to improve the idea through trial and error.

Pretotype made of cartoon

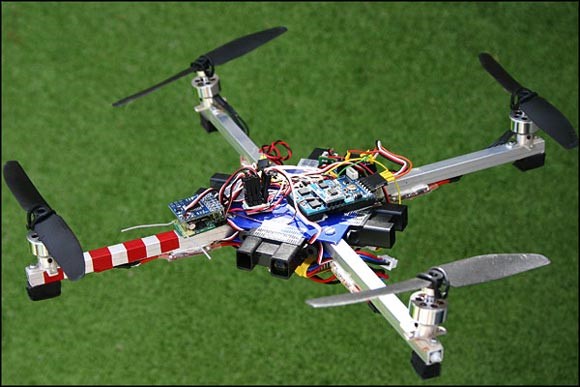

Starting points for production of a prototype (Picture 2, 3)

- Work professionally - in terms of both functionality and design

- Avoid unnecessary costs - use of standard components, commercially available components, advanced technology prototyping

- think about the balance of the price – functionality - design (cost performance).

- Avoid unnecessary "extra features" – the problem of inventors

Prototype of quadrocopter made mainly with standard parts (elise, motor) and partially inventor's developed parts (hardware and software)

A very useful tool is 3D printing, which is only one possibility for rapid prototyping.

The aim is to simulate its physical characteristics (in a case of a pot for preparing coffee)

Finished/presentation prototypes

These are the prototypes which you will use to demonstrate your idea to other people - in particular, to potential investors or licensees. They should look and perform as much as possible like a finished product. The main reasons are:

- Most potential investors or licensees will want to see ideas with as few unresolved problems as possible, because that reduces their risk.

- Few people have the ability to look at a rough early prototype and visualise a finished, quality product.

- The closer your prototype is to a finished product, the more you will learn about the design, production and cost aspects of your idea. This knowledge will be invaluable when you need to convince people of the technical and commercial viability of your idea.

For obvious reasons you need to prove - first to yourself, later to investors or companies - that your idea works.

For an invention that is a process or a business method, physical proof may not be possible or necessary. For an invention that is a substance (for example, a new kind of shampoo), samples to test may be sufficient. For a manufacturable product, you need to show it looking as close to a finished article as you can manage or afford.

For the first prototype (pretotype) you can use:

- handy materials (wood, paperboard, LEGO…)

- more complex technical products - part of the elements is omitted (trivial functioning: e.g. a device intended for safety signaling, which starts at nightfall - nightfall sensor is omitted).